Leaders in

Liquid Level Measurement

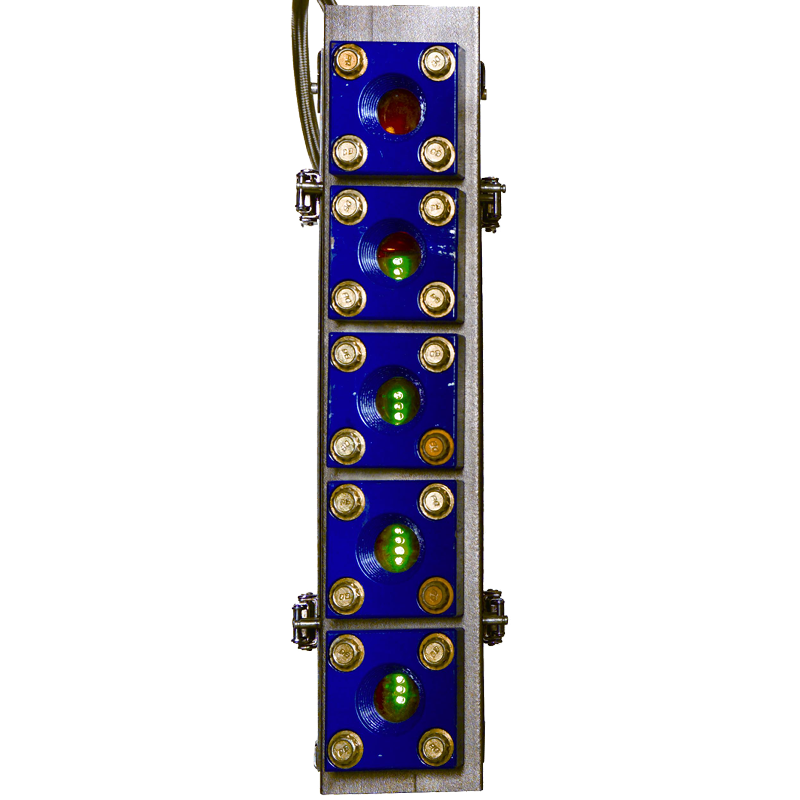

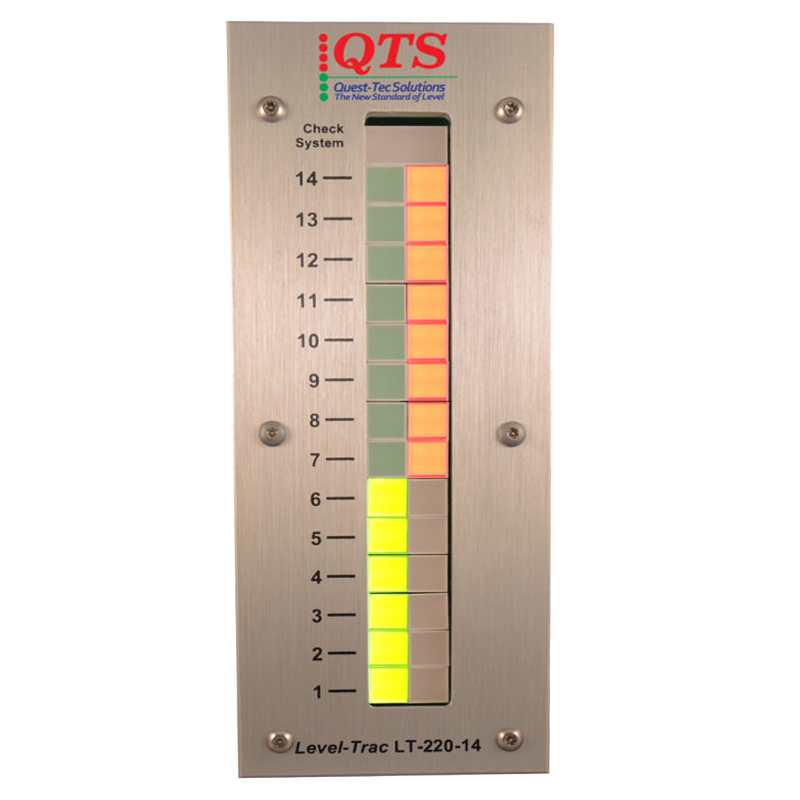

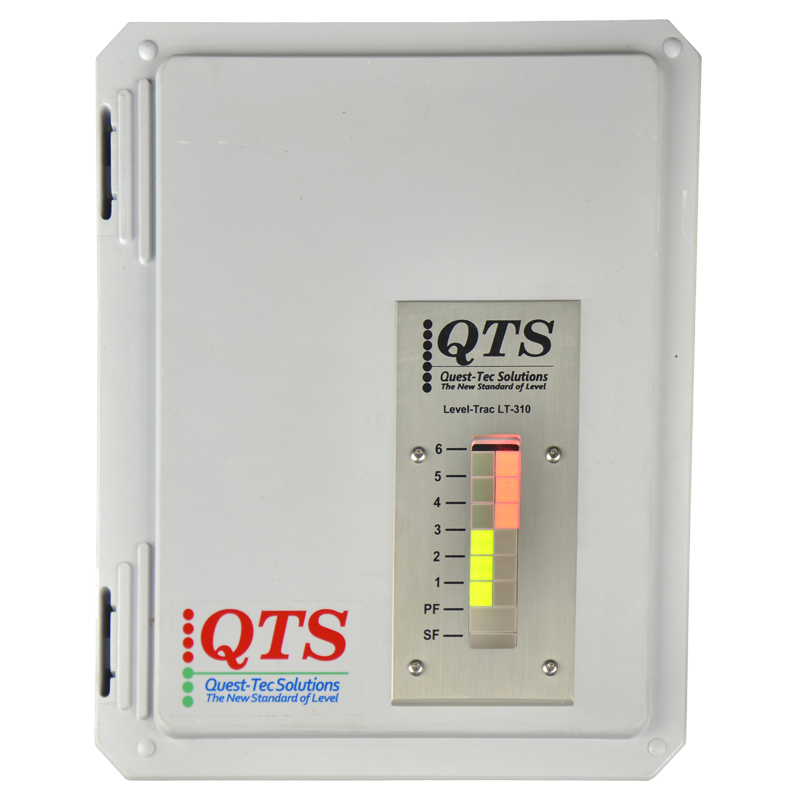

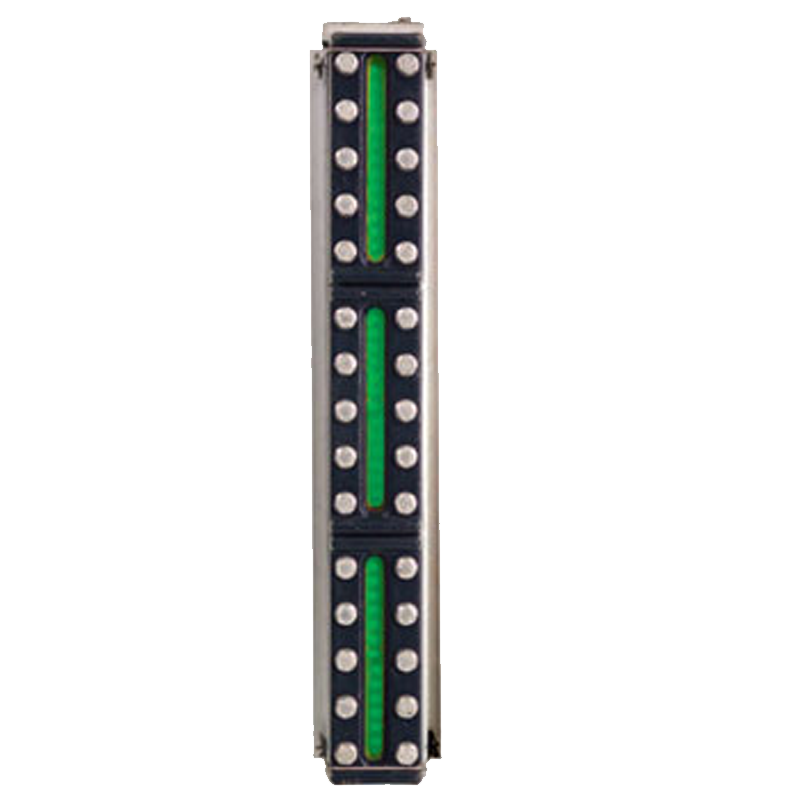

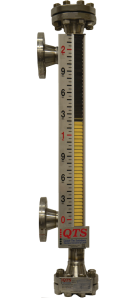

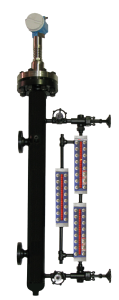

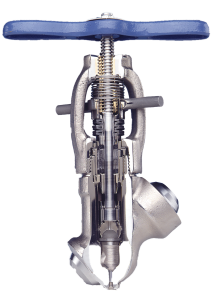

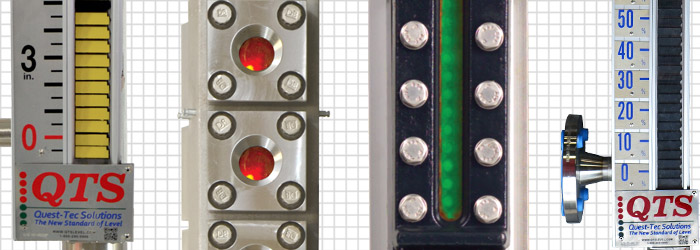

Quest Tec specializes in the development, engineering and manufacturing of liquid level gauges and valves, steam gauges, Capacitance Columns and Switches, Magnetic Gauges, Armored Tubular and Sight Flow Indicators for various markets.

Our Best Sellers

Check out our most popular products or browse our full product line.

3D Configurator

Check out our new 3D Configurator! Customize your product, generate CAD files, and request a quote!

Our History

Questtec Solutions is a young company with a long lineage of quality, experience and care. The development and engineering of the liquid level gauge and valve product lines began more than forty years ago. We carry a full line of magnetic level gauges and magnetic level indicators, steam level indicators, and liquid level indicators. These products have been consistently refined and improved to remain one of the industry leaders in liquid level measurement. One of the leading liquid measurement companies, Daniel Measurement and Control, directed this product development and engineering. This certification is a testament to the same high quality standards from which our customers have always benefited. Questtec Solutions provides companies with flexible solutions to specific needs rather than adapting existing products to meet presented circumstances. As a leader in liquid level measurement innovation, we will continue to offer the quality and performance customers expect.

Products

Quest Tec specializes in the development, engineering and manufacturing of liquid level gauges and valves, steam gauges, Capacitance Columns and Switches, Magnetic Gauges, Armored Tubular and Sight Flow Indicators for various markets.

Channel Partners

Quest Tec is an International Company with Representatives based throughout the world. Our Partners can assist with Commissioning Start Up and Calibration, 24 Hour Service and Repair Support.

Application Matrix

Not sure what type of level product you need for your application? Our product matrix provides a listing of our products based on Pressure, Temperature, Market, Indirect, Direct, Boiler Code Requirement, limitations and other.

Latest News

Latest news, tips, and podcasts.

Magnetic Level Indicators vs. Gauge Glass: Understanding the Differences for ASME Section I Applications

Understanding these differences is essential for ensuring code compliance, maintaining plant safety, and making informed decisions about level measurement investments. And the distinction goes far beyond simple technology preferences. It affects system design, installation requirements, and operational safety protocols as well.

11 Reasons Why Correct Level Measurement of Boiler Water Is Essential for Plant Safety and Compliance

From small industrial facilities to massive power generation plants, proper level monitoring prevents disasters while ensuring regulatory compliance and operational efficiency.

11 Magnetic Level Indicator Design & Code Rules for ASME Section I Boilers

When specifying magnetic level indicators for ASME Section I boiler applications, compliance with specific design and code rules is non-negotiable. These regulations ensure safe operation and regulatory compliance in steam boiler systems. Here are the 11 essential rules every engineer must follow.